Intel Investing $3.5B in New Mexico Fab Upgrade, Boosting US Chipmaking

Intel recently announced plans to invest $3.5B in a new state-of-the-art Fab upgrade in New Mexico to boost US chipmaking capabilities. This is expected to create hundreds of jobs in the region and could be a huge boon for the economy.

In this article, we’ll have a look at the details of Intel’s investment, what it means for the state of New Mexico, and why the move is so important for the US chip-making industry:

Intel Investing $3.5B in New Mexico Fab Upgrade

Intel Corporation has announced that it will invest approximately $3.5 billion in its Rio Rancho, New Mexico fab as part of a plan to upgrade the existing facility and build a new one. The investment will create 1,500 high-tech jobs in the area and make Intel more competitive in the global semiconductor industry.

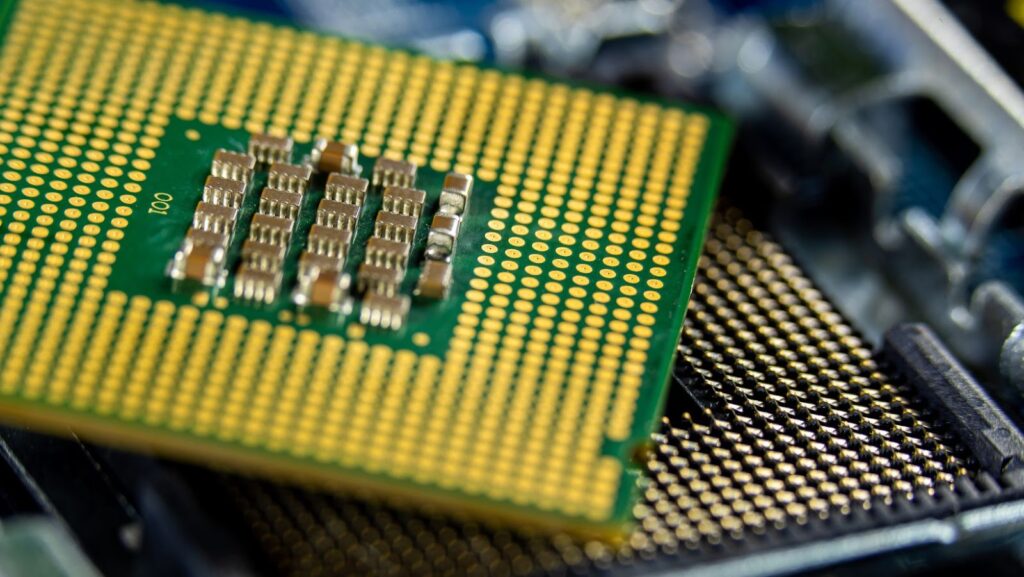

The upgrade is significant and will include new construction, new equipment, and improvements to existing infrastructure that have not been seen at this site in decades. In addition, Intel’s investment will lead to increased output of advanced manufacturing capabilities at Intel’s Rio Rancho facility – producing leading-edge performance products such as 10 nanometer (nm) microprocessors, 3D memory products built on Intel’s process technology, and radio frequency (RF) transceivers for 5G networks. This investment decision deepens Intel’s commitment over the long term to its Rio Rancho employees and customers worldwide.

The fab upgrade project is expected to begin immediately on existing tools and buildings, with plans for groundbreaking on new buildings scheduled for mid-2021. Upon completion in 2024, the upgraded facilities are projected to add thousands of direct jobs from Intel alone across multiple operations like chip development engineering, advanced technology operations, metrology engineering and others; thousands more indirect jobs spread throughout multiple sectors like construction, security services provided by local companies; all supported by several additional local businesses driven by demand from our expansion.

Boosting US Chipmaking

Intel Corporation recently announced a $3.5 billion investment in its Fab 11X facility in Rio Rancho, New Mexico, as part of its plans to significantly increase chipmaking capacity and boost U.S. chip fabrication capabilities. Once complete, the new fab is expected to become one of the world’s most advanced semiconductor manufacturing sites.

The modernised Fab 11X will be Intel’s first new U.S.-based fab since 2011 and is expected to employ approximately 2,000 people including engineers and technicians committed to delivering innovative products for the industry-leading Intel Core processor family and future technologies like artificial intelligence (AI).

The upgraded fab will also focus on creating leading edge computing platforms serving data-centric workloads such as 5G networks, edge computing architectures and AI accelerators which are essential for fueling digital transformation across various industries from automotive to retail worldwide.

Fab 11X will also feature production equipment capable of utilising multiple nodes of process geometry for different technologies—from 180nm up to 7 nm or even lower—enabling Intel’s world-class integrated device engineering and manufacturing (IDEM) technology platform capable of rapidly bringing high-complexity products quickly into production with exceptional quality and reliability standards that have come to define Intel’s industry leadership in chip making capabilities.

Additionally, this significant investment ahead of the predicted shortage in more advanced chips signals a commitment by Intel towards diversifying its product portfolio while at the same time helping strengthen US semiconductor leadership globally to narrow the gap between itself and rival TSMC who has built a strong lead manufacturing complex chips on smaller node processes than anyone else right now in terms of sheer capability.

With this new upgrade by Intel coming online soon enough, US chip makers can look forward to further shoring up their processors certifying them “Made In USA” with breakthrough microarchitectural designs gaining traction not just within America but around the world as well owing largely due US based innovation led by big names such as Intel Corp just now beginning redefine global digital trends all over again!

Background

Recently, Intel has announced plans to invest $3.5 billion in upgrading its New Mexico fab, boosting US chipmaking. This investment marks the largest single investment in Intel’s history and is set to create over 1,000 jobs in the local area.

This new fab project will be highly significant for the US semiconductor industry, as it will lead to the production of Intel’s state-of-the-art chips and support other US chip suppliers.

Let’s take a deeper look at the background of this significant investment:

US Chip Making Industry

The US chipmaking industry has received limited attention in the last few decades, having witnessed the emergence of countries such as Taiwan, China and Malaysia as major players in the semiconductor field. However, advancements in chip-making technology have driven a shift in sentiment towards the industry as more nations invest heavily to gain key positions within the global supply chain.

According to a senior analyst from IC Insights, the US has continued to dominate capital expenditure (CapEx) for chipmaking, making up over 40% of total global spend in 2020. This is largely due to big investments by Intel Corporation which recently announced its plan to invest $3.5 billion into its New Mexico manufacturing facility upgrade, further cementing its position at the forefront of the semiconductor manufacturing sector.

As Intel takes a decisive move towards advanced logic chip production with this groundbreaking investment, other tech companies have followed suit; Google Cloud investing $1 billion into an AI chip factory and Facebook deploying $600 million into the research and development of 5G equipment enablement chips are just some examples of serious investments being taken by firms that recognize the significance of this fast-growing sector.

Intel’s Investment in US Chipmaking

Intel Corporation announced that it will invest more than $3.5 billion over the next seven years to upgrade and expand a 30-year-old chipmaking factory in Rio Rancho, New Mexico. This investment is expected to create 1500 jobs in the United States and indicates Intel’s commitment to supporting the chipmaking industry in America.

Intel has been investing heavily in their US, European and Israeli facilities since 2018, when they acquired Movidius and FPGA manufacturer Altera, which has now added to their portfolio of technologies used for artificial intelligence applications. Additionally, Intel plans to develop a 5nm manufacturing process by 2021–2022. This modernization of chip technology will support faster computing power that can help with multitasking, such as editing photos or streaming video with minimal impact on battery life.

Intel’s focus on excellence in chip fabrication is inspired by the success of Taiwan Semiconductor Manufacturing Co., Ltd. (TSMC), the world’s leading independent semiconductor foundry service provider for the global chip market. However, Intel’s main focus is not just competing with TSMC; instead, it involves creating data centres on U.S soil as part of its plans for local production and support of itself and other tech companies.

This announcement further shows Intel’s commitment to investing in local communities and strengthening its production capabilities worldwide – this includes supporting small businesses throughout both developing countries like India and established markets like USA and UK where tech firms are growing rapidly due to new regulations surrounding online presence and access to data storage solutions.

Intel’s New Mexico Fab Upgrade

Intel has recently announced plans to invest $3.5 billion in a New Mexico fabrication plant upgrade. This investment marks a major milestone for US chip manufacturing, as Intel is one of the major providers for tech products. It is predicted that this investment will positively impact the local economy, working to boost job growth and improve the technology sector in the state.

Let’s explore Intel’s new New Mexico fab upgrade and what it will mean for US chipmakers:

Purpose and Scope

Intel is investing $3.5B to upgrade its Fab in Rio Rancho, New Mexico. This project will update a 20-year-old factory and involve the construction of a new state-of-the-art 300mm wafer fabrication facility to manufacture Intel’s most advanced technology products. The Fab Upgrade is part of Intel’s global manufacturing network which currently includes 32 top-tier manufacturing facilities in more than 15 countries.

The purpose and scope of the Fab Upgrade is twofold:

- It will provide Intel with additional capacity to meet high customer demand for Intel products.

- It will provide Rio Rancho with new economic opportunities by creating hundreds of high tech jobs.

The upgrade includes plans to modernise the existing infrastructure around the factory with increased water and energy efficiency, environmental protection initiatives such as water recycling systems, and renewable energy sources such as solar and wind technologies. The project also supports job training initiatives and collaboration with local university partners.

Benefits to US Chipmaking

The Intel New Mexico Fab Upgrade is an investment of $3.5 billion by Intel to upgrade its manufacturing facility in Rio Rancho, New Mexico. This upgrade will result in more advanced chipmaking capabilities, expanded research and development facilities and the creation of 400 new high-tech jobs in the area. It is a part of a larger campaign by Intel to re-shore its semiconductor manufacturing production from abroad back to the United States.

The investment will be beneficial to US chipmaking on multiple fronts. First, it will increase competition in price and quality, leading to advancements across the industry. Intel’s technology has long been a provider of top-of-the-line semiconductors for enterprise and consumer level applications. The stationing of these high-tech jobs at home will boost economic activity throughout the state and attract other tech companies who may decide to locate or expand in New Mexico due to this investment from Intel. Additionally, updated testing infrastructure due to this project could make it easier for even smaller companies outside of Intel’s scope to further modernise their processes with faster digitization than would be possible internationally then fewer resources domestically remain unregulated or unaccounted for in transit compared if say a company cares about sustainable data operations.

More broadly, the ongoing development of US foundries is essential for the nation’s security since they are increasingly tied with various defence projects, AI/ML endeavours, Internet of Things (IoT) applications etc – all areas considered integral components now more next generations innovation initiatives requiring sophisticated data capture an analysis capabilities outpacing what may be available overseas that prove vulnerable especially during trade disputes or political issues creating tension between both sides thereby incentivizing domestic production cycles with tighter control over usage scenarios none can compare native resource capacities without cost prohibitive concessions offshore whenever possible less risking potential pitfalls down stream requiring extra attention helping minimise any potential liability unfavourable decisions export protocols require thus strategic investments made stateside confer greater latitude designing far reaching architectures facilitating unthinkable outcomes as yet unforeseen before ever being deemed necessary.

Intel’s Commitment to US Chipmaking

Intel recently announced their commitment to invest $3.5B in New Mexico for a state-of-the-art advanced computer chip factory. This new factory upgrade is a major boost to US chipmaking and is part of Intel’s strategy to strengthen its US chipmaking operations.

This new factory upgrade is expected to create thousands of high-paying jobs while helping US chip makers compete in the global chip market.

Intel’s Commitment to US Chipmaking

Intel has a long and proud history of investing in the United States, with over $25 billion in investments and construction projects since 2000. The Intel team is committed to supporting advanced chip manufacturing in the US and enhancing US innovation through investments in cutting-edge manufacturing capabilities.

By upgrading its Rio Rancho, New Mexico fabrication plant, Intel is committing to doubling investment by 2025—from $3.5 billion today to up to $7 billion. This upgrade will create up to 1000 new high-tech jobs that contribute to a bright future for communities across the US base for high-tech growth.

Intel supports U.S.-based chipmakers through supplies of advanced technology, design engineering capabilities, industry best practices, and its extensive R&D efforts. Intel believes that this type of investment will enable greater advancements in chip technology while creating more opportunities for knowledge sharing and collaboration among industry leaders and more job opportunities for skilled professionals across the country.

Additionally, with this commitment to keeping chip production local rather than outsourcing it abroad, Intel expects an immediate increase in investment by industry partners and public-private partnerships seeking advancements in highly cooperative environments while minimising dependence on shipments via foreign production costs.

With over 500 projects spanning 50 states—including their efforts at the Rio Rancho facility—Intel shows no signs of slowing its commitment to U.S.-based chipmaking anytime soon with contributions towards both economic output and job growth along the way.

Impact of Intel’s Investment

Intel’s investment in a new chip-making facility accents the ever-growing importance of the semiconductor industry. This investment highlights the crucial role of semiconductors in powering innovation across all industries, and it reinforces Intel’s commitment to US chip development and manufacturing.

The latest $3.5B factory upgrade is being built in Rio Rancho, New Mexico and is expected to house some 3,000 employees upon completion in 2024. This sizable investment shows Intel’s commitment to preserving its leadership position in the semiconductor industry on a global scale. In addition, the new facility will help foster research and development capabilities within the US better than before due to its proximity to universities and Intel labs in New Mexico.

On initially assessing potential sites for this venture, Intel acknowledged that Texas may have provided a desirable business climate for businesses looking for growth as well as low operating costs; however, with its long established presence in New Mexico since 1980s, Intel chose Rio Rancho for its new factory insisting that cultivating innovation with local partners was more important than saving costs on the capital expenditure side.

This deliberate decision underscores Intel’s pledge of making U.S.-based chip manufacturing world class. In addition to directly providing U.S jobs and infrastructural investments, this latest commitment by Intel is sure to yield major dividend returns at both micro and macro level given expectations of increased consumer demand, competitive advantages over other suppliers due to superior product quality assurance measures obtainable with U.S made components being sold abroad as well as catalysing further RD activites by subcontractors operating within related industries like AI & Cloud computing et al given their accesssercivity to cutting edge technology inventions serviced by players such as IBM & Microsoft historically headquartered on US soil for decades now!

Conclusion

Intel’s $3.5 billion investment in New Mexico is great news for the US chipmaking sector, creating jobs and allowing the company to build a new Advanced Manufacturing Facility, enabling them to expand their computing and artificial intelligence capabilities. In addition, with Intel’s commitment to modernising their chipmaking capabilities in the US, the company is taking a big step forward in the industry and helping to ensure US chipmaking remains globally competitive.

Intel’s Commitment to US Chipmaking

Intel’s commitment to US chipmaking is more significant than its $3.5 billion investment in New Mexico. The upgrade indicates Intel’s dedication to promoting technical innovation and economic growth in the United States. With this investment, Intel is pursuing next-generation semiconductor technology that will enable them to remain competitive within the global market and strengthen their presence across various sectors, from consumer products to enterprise applications.

The project reflects Intel’s confidence in utilising the intellectual, physical and capital resources available in New Mexico and surrounding areas. This expansion also implies that other states may benefit from similar investments depending on what resources they can bring for chip production on US soil. Additionally, as US companies expand their local operations as part of their corporate expansion strategy, these investments can bring added job opportunities to further bolster economic prosperity.

As Intel ramps up chip production with this upgrade at Fab 11X in New Mexico, additional effects can be seen throughout all 50 states trickle down the line – practices such as creativity and knowledge dispersion through collaborative problem-solving initiatives will only aid engineers from all backgrounds and training levels alike considering that semiconductor fabrication relies on many disciplines beyond computing technologies such as architecture and engineering. Ultimately, this expansion could spark further growth for other technology firms both large and small within the United States generated through partnerships & collaborations with domestic providers of goods & services could assist suppliers serving specific sectors necessitating items such as chipsets or components used by consumer electronics manufacturers or military suppliers.

Altogether by helping spur development activity and employment gains in high-tech industries where there has been steady decline lately due to offshoring activities & mergers among industry leaders, Intel’s investment in Fab 11X should have a lasting impact which extends far beyond its borders on US innovation & competitiveness for years to come leading soon an increased revenues generated among tech manufacturing companies across America!

Benefits of Intel’s Investment in US Chipmaking

Intel’s $3.5B investment in New Mexico will produce multiple benefits for the US chip making industry. First, it will bring hundreds of jobs to New Mexico and provide an economic stimulus to the region, while further progressing the country’s quest for semiconductor self-sufficiency.

Intel’s decision to expand its existing manufacturing capacity in New Mexico also strengthens the country’s ability to compete on a global level in semiconductor production and innovation. The upgrade will enable Intel to achieve greater economies of scale, improved efficiency, and increased production capabilities to help meet growing demand domestically and internationally.

In addition, Intel’s enhanced modernization facility in Rio Rancho allows them to refine their current manufacturing process technologies with more advanced methods such as using extreme ultraviolet (EUV) lithography systems – giving them a competitive advantage over other chip makers both in terms of product quality and cost savings offered through automation.

From an environmental perspective, increased efficiency from automation helps reduce water usage. In addition, it emits fewer pollutants – saving costs on energy bills and making Intel’s production processes more sustainable – alluding to reduced operational impact on the environment overall.

All of this is why Intel’s decision is positive news for US chipmaking: their investment helps create jobs, promote regional economic growth, advance chipmaking technology developments, increase domestic competitiveness in global markets, improve efficiency/cost savings – all eventually contributing towards a more sustainable environment – which are all essential building blocks towards a stronger base for America’s technological advancements.

tags = intel semiconductor comoany, multinational corporation and technology company, intel daya center solutions investment, intel chip making, intel ceo pat gelsinger, chip manufacturing plant, intel to rejuvenate manufacturing, intel chipmaker company, intel new ceo gelsingershanklandcnet, intel mexico ceo gelsingershanklandcnet, intel ceo upgrade plan, intel chipmaking progress, processor packaging technology called foveros

More Stories

Popular HONOR Laptop Picks for Black Friday: Deals You Can’t-Miss

The Dangers of Online Addiction

What has Been Robinhood’s Involvement in the GameStop Situation?